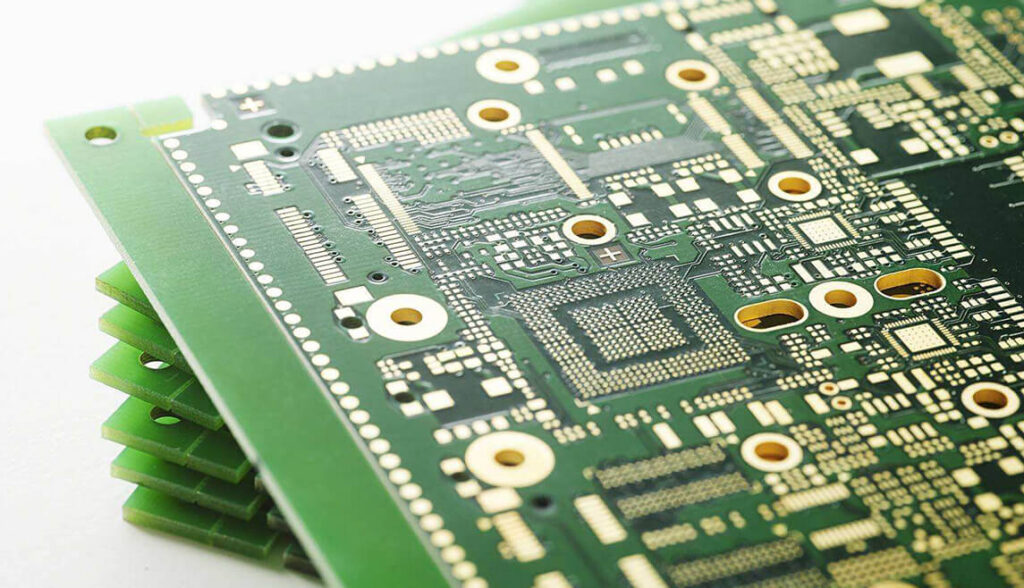

Additives to Enhance the Performance of Printed Circuit Board Inks

Synopsis:

In the intricate world of electronics manufacturing, printed circuit board (PCB) inks play a vital role in creating the complex pathways that power devices. In order to improve the physical properties of PCB inks, the printability of the inks is enhanced and printing results are improved. In this article, we will reveal what additives are tailored to PCB inks.

Composition of additives in PCB inks:

Resins, solvents, pigments, and co-additives are the main components of PCB inks, but only the co-additives are the alchemists who fine-tune the properties of PCB inks to give them optimum performance in electronic applications. Let’s take a closer look at the synergies between PCB inks and these co-additives:

Dispersibility: To reduce pigment grinding time and prevent pigment flocculation, we have developed BZ-110A wetting and dispersing additive, which has good resin compatibility and improves wetting, viscosity reduction and dispersion of various colours. Ensure the colouring strength of the circuit design.

Anti-foaming agent: In order to inhibit and eliminate the air bubbles generated during the production, filling and construction of ink, especially for the elimination of air bubbles of high-viscosity ink, we have specially developed BZ-6800A silane-modified anti-foaming agent, which is suitable for epoxy system.

Levelling agent: In the process of ink preparation, surface tension is easily generated, making the ink surface wrinkles and bubbles and other phenomena, which will affect the quality of printed products, the addition of BZ-603 levelling agent can effectively reduce the surface tension, improve the smoothness of the surface of the ink and wettability, and to solve the phenomenon of shrinkage and skinning caused by the rise in viscosity of the paint, making the ink more stable and smooth in the printing process.

Revolutionise the performance of printed circuit board inks with Camen Chemical(cmadditive.com)

By integrating tailor-made additives, PCB inks reach unrivalled heights of reliability and efficiency, offering a range of benefits that redefine their role, they improve the performance and quality of the inks, and guarantee the quality and effectiveness of the printed product. Of course, the co-ordination and selection between the various auxiliary additives needs to be tailored to the specific situation to achieve better results.

Summary:

In electronics manufacturing, co-additives are the architects of precision and reliability, giving PCB inks qualities that exceed traditional expectations.Whether it’s improving dispersion efficiency, enhancing wetting, eliminating air bubbles or improving ink smoothing properties, cmadditive additives give a great result. Take advantage of the transformative power of additives to take your PCB inks to new heights of precision, reliability and performance, ensuring that the heart of electronic devices beats perfectly.

People who read this article also read the following articles: